Noise and sound pollution have become common phenomena in the aviation industry. Therefore, aircraft sound insulation is crucial to reduce noise levels. Acoustic foam is one of the effective sound insulation materials, which has been used in the aviation industry for many years.

In this blog post, we will discuss how acoustic foam can be used as a sound insulation material and its benefits in the aviation industry

Acoustic foam is used in the aviation industry to reduce noise levels. Foam can effectively reduce low-frequency and high-frequency noise. This provides passengers with a more comfortable experience as they are not affected by aircraft engine noise. In addition, acoustic foam helps control vibration. This is important because it helps reduce the wear and tear of aircraft components.

There are many advantages to using acoustic foam in the aviation industry. The comfort of passengers has been improved as they are not affected by aircraft engine noise. In addition, improved noise control can reduce the wear and tear of aircraft components. The use of acoustic foam also helps to improve vibration control, which helps to improve the cabin noise on modern aircraft so much that passengers cannot bear it. In fact, the noise level has been measured at 90 decibels, equivalent to a running chainsaw. This makes it almost impossible to have a conversation, and even impossible to hear safety briefings from flight attendants. Therefore, many passengers feel frustrated and uncomfortable during the flight.

For various reasons, it is important to reduce the noise level inside the aircraft cabin. Perhaps the most obvious reason is that it provides passengers with a more enjoyable experience, as they do not have to listen to the engine buzzing and other environmental sounds for several hours in a row. But reducing cockpit and passenger noise also poses safety risks, as it allows for more effective communication between crew and pilots, and can even improve performance during takeoff and landing. Acoustic foam is one of the commonly used materials to achieve these results, so let's take a closer look at what it is and how it works

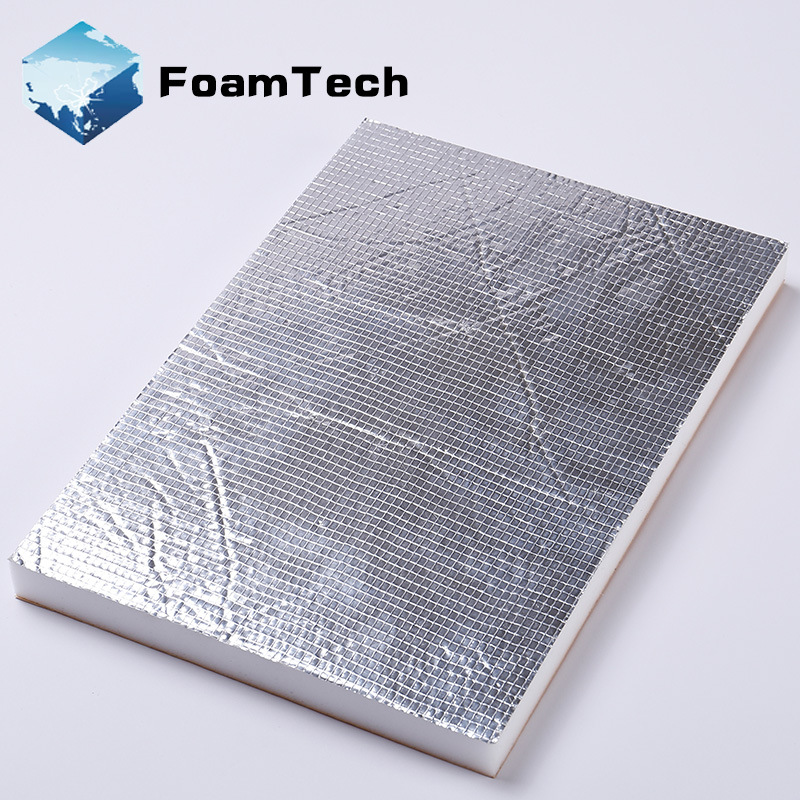

Melamine sponge foam board is a flame retardant and noise control material, which can be installed on the wall and ceiling of the aircraft cabin. They are also very effective in vibration control. Due to its effectiveness, Fengtai High Tech's melamine sponge has an internal porosity rate of up to 99%, and the comprehensive noise reduction coefficient (NRC) detected by SGS is 0.95. It makes sound waves enter the internal structure of foam conveniently and effectively, and are consumed and absorbed by the three-dimensional network structure, never effectively eliminating the reflected wave of sound waves. Melamine sponge foam board has been used in various applications, including aircraft cabin, power plant and construction site. In addition to flame retardancy and noise control characteristics, melamine sponge foam board also has waterproof property and high R value, making it an ideal insulation material. If installed correctly, melamine sponge foam board can provide significant advantages in fire prevention, noise reduction and vibration control.

Melamine sponge foam board has many applications in aircraft cabin. They can be used for flame retardancy, noise control, and vibration control. The foam board is also easy to install. The flame retardancy of foam board makes it an excellent choice for use in aircraft cabins. They can help prevent the spread of fires and protect passengers and crew members in the event of a fire. The foam panel also has good noise reduction performance, making it an ideal choice for use in aircraft cabins. They can help reduce the noise level inside the cabin, making passengers and crew more comfortable. Foam board also has good vibration damping performance, making it an ideal choice for use in aircraft cabins. They can help reduce the vibration level inside the cabin, making passengers and crew more comfortable.

Acoustic foam is used in the aviation industry, especially as a sound insulation material when the aircraft is flying at high altitude. This is due to the light weight of melamine foam compared with other foam. Compared with polyurethane foam, in other alternatives, melamine foam can provide low-frequency and high-frequency isolation without using sufficient thickness. Considering that passenger comfort is very important in the aviation industry, and with the increase of air traffic, people pay more and more attention to noise control and vibration control, so melamine foam has been well applied in the industry. Its use can reduce noise and improve passenger comfort during flight. In addition, its excellent vibration reduction performance.

The aviation industry is one of the most technologically advanced and complex industries in the world. Aircraft need to meet strict noise certification standards. Manufacturers use various technologies to ensure that the aircraft is as quiet as possible. A common method is to install sound absorbing foam, which helps absorb and reduce unwanted sound. Acoustic foam has a variety of colors, textures and sizes, making it a multi-functional sound insulation material suitable for many applications. In this blog post, we will discuss the different types of acoustic foam available on the market and how to use them to improve aircraft noise levels.